Your Position:Home>Products>Teflon Heat Exchangers>Anticorrosive Fluoroplastic(PFA/PTFE/FEP) Heat Exchangers

Product Detail

In

highly corrosive media, the process of exchanging heat between two

fluids is extremely critical. Its success depends not only upon the

mechanical properties of materials, but also their resistance to the

combined elements of chemical attack, high temperatures and pressures.

There

are many exotic materials that can be used to handle corrosive

chemicals, such as special glass,titanium, zirconium, tantalum, and

chrome/nickel containing alloys. However, a short service life may be

expected.

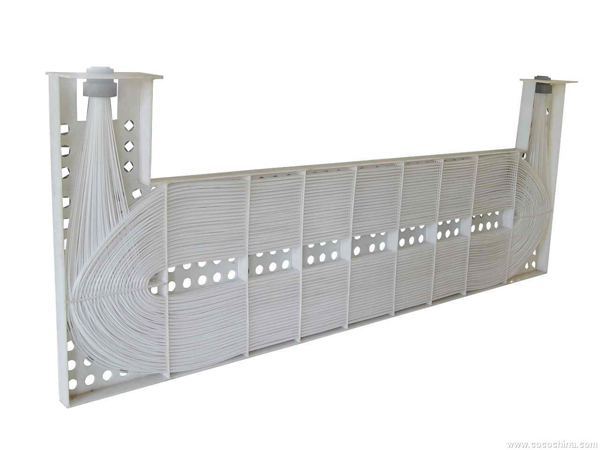

SURPLUS

fluoroplastic heat exchanger is an all plastic heat exchanger designed

specifically for heating or cooling highly corrosive media. It is made

of fluoroplastics such as PTFE, FEP and PFA, also known as Teflon

(DuPont). The extreme chemical inertness of fluoroplastic and its

flexibility in fabrication make it an ideal material of construction in

many chemical processes. Its smooth surface tends toward very low

contamination and incrustation, even in extreme applications. This

enables use of the SURPLUS fluoroplastic heat exchanger in applications

where metal exchangers require frequent maintenance to remove buildup

from exchanger tubes.

Advantages of SURPLUS Fluoroplastic Heat Exchangers:

1. Superior corrosion resistance to most acids and solutions.

2. Large heat transfer surface in a confined space.

3. All-plastic design with no elastomers, seals or mechanical joints.

4. Plastic design eliminates effect of stray current in plating applications.

5. Open flow tube bundle–tubes do not touch.

6. Exceptionally low fouling factors.

7. Tough, impact resistant tubes, not capillary-type tubing.

8. Low pressure drops enhancing turbulent flow resulting in maximized heat transfer capability.

9. Handle steam up to 35 psig saturated.

10. Easily repaired at plant site with a hot air welding gun.